hardness test scalecales|rockwell hardness test diagram : trader The Rockwell scale is a hardness scale based on indentation . Aproveite a gratuidade total da redecanais web e descubra uma nova e excitante forma de desfrutar do entretenimento online. Os maiores sites de futebol do Brasil são Globoesporte, ESPN Brasil, Goal.com Brasil, Futebolplayhd.club, Torcedores.com e 90min Brasil. Esses sites oferecem notícias, resultados, estatísticas, vídeos e muito mais .

{plog:ftitle_list}

Resultado da Disponível para baixar e aproveitar. AppleTV GOOGLE PLAY. Os Incríveis 2. Quando Helena Pêra é chamada para voltar a lutar contra o crime como a super-heroína Mulher-Elástica, .

typical rockwell hardness of materials

The Mohs Hardness Scale is a widely recognized and simple scale for measuring the scratch resistance of various minerals. Created by Friedrich Mohs, a German geologist, in 1812, it remains a standard in geology, .

types of hardness testing methods

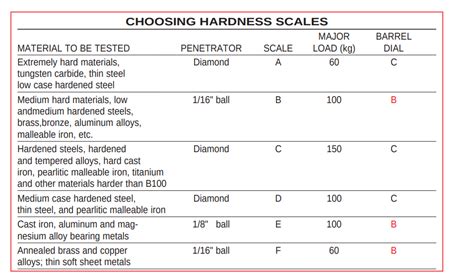

The Rockwell scale is a hardness scale based on indentation .ASTM E18 contains a listing of all regular Rockwell scales and typical materials for which these scales are applicable. Use these tables in selecting the scale that is appropriate for your application.

The Mohs scale of mineral hardness is a qualitative ordinal scale, from 1 to 10, characterizing scratch resistance of minerals through the ability of harder material to scratch softer material. The scale was introduced in 1812 by the German geologist and mineralogist Friedrich Mohs, in his book Versuch einer Elementar-Methode zur naturhistori. The Mohs hardness scale is a qualitative test that measures the hardness of a mineral by its ability to visibly scratch softer minerals. The scale isn’t perfect, but it’s a great tool for quick identification of rocks in the field.Devised in 1812 by German mineralogist Friedrich Mohs, the Mohs Hardness Scale is a relative scale that ranks minerals based on their ability to scratch one another. It consists of 10 standard minerals, each assigned a specific hardness value from 1 (softest) to 10 (hardest).

What is Mohs Hardness Scale? The Mohs Hardness Scale is a set of ten reference minerals (numbered 1 through 10) that are used to determine the relative hardness of minerals and other objects. In this test the hardness of a .

Mohs Hardness Test: A qualitative scale that ranks minerals from 1 to 10 based on their scratch resistance. For example, talc is rated 1, while diamond is rated 10. Shore Hardness Test: Used for softer materials like . The Moh's (Mohs) scale of hardness is the most common method used to rank gemstones and minerals according to hardness. Devised by German mineralogist Friedrich Moh in 1812, this scale grades minerals on a scale from .

types of hardness testing machine

types of hardness scales

Circle sample cutter store

Rockwell hardness test using Rockwell hardness scale is one of the extensively used and accurate hardness test methods prevalent in industries for thin steel, lead, brass, zinc, aluminum, cemented carbides, iron, titanium, copper alloys, .

Mohs hardness, rough measure of the resistance of a smooth surface to scratching or abrasion, expressed in terms of a scale devised (1812) by the German mineralogist Friedrich Mohs. . the test may only loosen grains without testing individual mineral surfaces; thus, certain textures or aggregate forms may hinder or prevent a true hardness .

Two inline skate wheels with different durometer – 85A and 83A Digital Shore hardness tester. The Shore durometer is a device for measuring the hardness of a material, typically of polymers. [1]Higher numbers on the scale indicate a . This image contains a table relating mineral hardness for a few selected minerals with common objects that could be used to test hardness. The title, Mohs Hardness Scale is accompanied with the National Park Service arrowhead symbol. The minerals are listed from hardest to softest with their hardness scale number as follows: Diamond, 10 .

Brinell hardness test is an indentation hardness test. It uses a hard spherical ball (usually around 10mm in diameter). An applied force (a typical test will use 3,000 kilograms) pushes the ball against the surface of the material for a set amount of time (between 10 – 30 seconds, known as the dwell time).Many Rockwell test standards also stated that while processing the test, there should be a distance of more than 2.5 times the diameter of the indentation between mid of an indentation and the periphery of the material. Thickness of Test Material In the Rockwell hardness test, indentation depth depends on the thickness of the material.

The Meyer hardness test; The Knoop hardness test; Other hardness scales. Hardness scales may also refer to: Methods of measuring the deposit formation by hard water. The scale of Pencil hardness This page was last edited on 11 February 2022, at 22:38 (UTC). Text is available under the Creative Commons .A variety of hardness-testing methods are available, including the Vickers, Brinell, Rockwell, Meyer and Leeb tests. Although it is impossible in many cases to give an exact conversion, it is possible to give an approximate material-specific comparison table for steels. Hardness comparison table. When the Brinell hardness (HB) exceeds 450 or the sample is too small, the Rockwell hardness test is used instead. This test involves pressing a diamond cone with a 120° top angle or a steel ball (1.59mm or 3.18mm in diameter) into the material’s surface under a specific load. The hardness is then calculated based on the depth of the .

The Mohs scale is only one of a number of scales used to assess mineral hardness. Others include the Vickers scale, Brinell scale, Rockwell scale, Meyer hardness test, and Knoop hardness test. While the Mohs test gauges hardness based on a scratch test, the Brinell and Vickers scales are based on how easily a material can be dented. The Brinell .The Janka hardness test (English: / ˈ dʒ æ ŋ k ə /; [1] German:), created by Austrian-born American researcher Gabriel Janka (1864–1932), measures the resistance of a sample of wood to denting and wear. [citation needed] It measures the force required to embed an 11.28-millimeter-diameter (7 ⁄ 16 in) steel ball halfway into a sample of wood.(The diameter was chosen to . Mohs Hardness Test: A qualitative scale that ranks minerals from 1 to 10 based on their scratch resistance. For example, talc is rated 1, while diamond is rated 10. Shore Hardness Test: Used for softer materials like elastomers and plastics, this test uses a spring-loaded indenter (durometer) to measure the depth of penetration. A durometer is .

Related reading: Metal Hardness Comparison Chart: HV, HB, HRC Commonly Used Hardness Brinell Hardness. The Brinell hardness test uses a ball made of hardened steel or a hard alloy with a diameter of D as the indenter.. A specified test force F is applied to the surface of the material being tested, and after a designated hold time, the test force is . A hardness of 85 A would be harder than a material with 70 A. A tire tread has a hardness of 70 A while a leather belt can have a hardness of 85 A. 90 Shore A is a hardness measurement of “90” using the Shore A hardness scale. Shore 90 A hardness is much harder than 70 A and 85 A. Materials with 90 A are rigid and cannot be deformed by hand.TableofContents ListofFigures ix ListofTables xii 1.Introduction 1 2.RockwellHardnessTest 2 2.1Significanceofthetest 2 2.2Rockwellindentationtestprinciple 2 2 .

Hardness generally refers to the resistance of a material to scratching or indentation, and a qualitative measure of the strength of the material. The most commonly used hardness tests are the Rockwell test, .

Before application of the Rockwell hardness test, you must prepare the surface of the material to be tested. The required surface condition for the Rockwell hardness test depends on the load used. The Rockwell hardness test is .

The Mohs Hardness Scale is a widely recognized and simple scale for measuring the scratch resistance of various minerals. Created by Friedrich Mohs, a German geologist, in 1812, it remains a standard in geology, mineralogy, and material science. The scale is qualitative, ranking minerals from 1 to 10, with 1 representing the softest mineral and 10 the hardest. The . The Janka hardness test is a variation or adaptation of the Brinell hardness test. The Janka scale ranges from 0 to over 4000lbf, with softer woods scoring lower on the scale and harder wood scoring higher. Some woods, like balsa, are very soft and have a low Janka score, while other woods, like oak, are much harder and have a higher score. .

The Vickers hardness test method was developed by Robert L. Smith and George E. Sandland at Vickers Ltd as an alternative to the Brinell method to measure the hardness of materials. The Vickers hardness test method can be also used as a microhardness test method, which is mostly used for small parts, thin sections, or case depth work. Since the . The Mohs hardness scale is the standard geologists and gemologists use to grade minerals and gemstones. They use the Mohs hardness test to determine "scratchability" of a material. So because diamond can scratch quartz, diamond is considered harder than quartz. It's pretty easy to perform this test in a lab or on your kitchen table.Indentation hardness value is obtained by measuring the depth or the area of the indentation using one of over 12 different test methods. Learn more about hardness testing basics here. The Rockwell hardness test method, as defined in ASTM E-18, is the most commonly used hardness test method. You should obtain a copy of this standard, read and .

A scale indicating the hardness of materials, first used in 1919, when it was invented by Stanley P. Rockwell.The measurement has no units. The symbol is HR followed by a letter indicating one of a number of possible scales, described in the table below. Mohs hardness test uses 10 reference materials of varying hardness as the scale for the test. The softest material used is talc (value=1) and the hardest material is diamond (value=10). Given that the references used for the Mohs scale do not have a graded increase, the Mohs scale lacks accuracy and is only a rough measure of hardness. .International Standards Organization – Rockwell Hardness Test Part 1 – Test Method (ISO 6508-1 Metallic Materials) The reason all steel product manufacturers use the Rockwell hardness scale is that it allows uniformity in reporting test results. Everyone in the steel industry recognizes the Rockwell hardness scale.The Mohs hardness scale measures a mineral's resistance to scratching. Find the traditional scale here and a chart of select gems ordered by hardness. MEMBERSHIP Search. Learning Center. Gemology. Science, tools, identification, treatment, valuation & grading of .

Some tests, like the Vickers hardness test, can be used on a macro scale as well as a micro scale. The loads required are listed in Table 1 below: Table 1: Different Hardness Test Methods and Their Corresponding Loads. Method Load Range Standard; Method. Brinell. Load Range. 1 kgf–3,000 kgf. Standard. ASTM E10, ISO 6506. Method.

rockwell hardness tester chart

rockwell hardness test diagram

23 de jun. de 2023 · Đón chào bạn đến với 09VIP – nơi mang đến sự tuyệt vời trong thế giới cá cược trực tuyến. Với 09VIP, bạn sẽ trải nghiệm một sân chơi với đẳng cấp và chất lượng hàng đầu. Từ những trò chơi đa dạng, giao diện thân thiện đến chương trình khuyến mãi hấp dẫn, tất cả đều được thiết kế để .

hardness test scalecales|rockwell hardness test diagram